-

Manufactured for the channel letter industry, the LETTERLOK 1800 reduces your channel letter fastening costs and is guaranteed to outperform the competition.

FEATURES

- New Development SPR (Self Piercing Rivet) tooling option

- Faster cycle times for increased production (60 – 80 cycles a minute)

- Greater capacity clinches 2” – 6” deep letters

- Adjustable table for operator convenience

- UL recognized clinch for channel letters

- Simple tooling adjustment for little or no set-up time

- Air powered (no electrical hook-ups necessary)

- Foot pedal operates lower tooling and clinch cycle for increased productivity

- Over 30 years of design experience, proven reliability and quality

- Affordably priced for low investment and faster payback

-

In two-stroke clinching, the material to be joined is first deformed plastically inside a die. In a second phase, the joint is created through a squeezing between the punch and anvil outside of the die. The result is a high quality joint in terms of shape, strength and repeatability.

In two-stroke clinching, the material to be joined is first deformed plastically inside a die. In a second phase, the joint is created through a squeezing between the punch and anvil outside of the die. The result is a high quality joint in terms of shape, strength and repeatability.WHATS INCLUDED

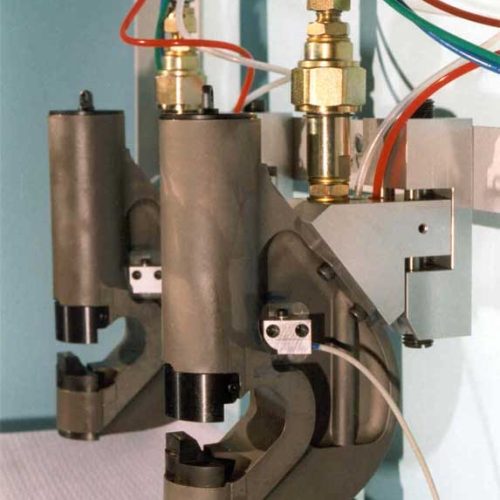

A complete ASTRACLINCH Power Line unit consists of a compact workhead connected through a hydraulic hose to an air-over-oil pressure intensifier (booster) with automatic cycle control, ready for connection to the factory compressed air net. An air preparation unit with pressure regulator, filter and water trap, a variety of tool kits, balancer and rotator are available as options.FEATURES

- Clinch up to 2 layers of 16 Gauge Mild Steel (.160" or 4mm total thickness)

- All Pneumatic Operation, uses standard 90psi (6bar) shop air.

- 2 stroke clinching operation.

- Stainless Steel Ready (up to .120" (3mm) total material thickness).

- Very Close Edge Access. Center of clinch within 1/4" (6.3mm) of flange edge.

-

A 10 tonne press custom designed with larger depth of C frame, capable of clinching up to 10 gauge material. This particular press featured a “dead man” switch foot pedal and integrated QC control safety monitoring. In addition to the full complement of round and rectangular tooling, its design allowed for hole punching and self piercing rivet capabilities.

A 10 tonne press custom designed with larger depth of C frame, capable of clinching up to 10 gauge material. This particular press featured a “dead man” switch foot pedal and integrated QC control safety monitoring. In addition to the full complement of round and rectangular tooling, its design allowed for hole punching and self piercing rivet capabilities. -

An automated floor-mounted machine capable of 3500mm x 2350mm platforms, this custom machine automatically sizes for an infinite variety of platforms with a stored library and bar code scanner. This particular machine has been a critical piece of equipment in crucial plant-line running parts since 2012.

An automated floor-mounted machine capable of 3500mm x 2350mm platforms, this custom machine automatically sizes for an infinite variety of platforms with a stored library and bar code scanner. This particular machine has been a critical piece of equipment in crucial plant-line running parts since 2012.FEATURES:

- A dual 10 tonne work head

- 5 foot depth of C frame

- Automated QC analysis software indicating clinch quality

- Full colour touch screen HMI (Human Machine Interface)

- Large entry and exit tables for part movement

- Full hydraulic and pneumatic automation

-

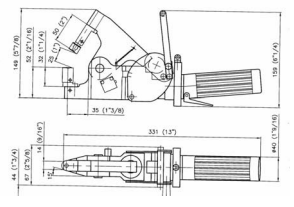

With a 12” depth of throat, this innovative design is the largest portable machine that we have built to date. This machine is a simple 4 tonne press and due to extensive FEA analysis, we were able to manufacture the product to weigh only 138 lbs! Strategically designed to reach into tight spaces, this design also features a rotating gimble allowing the operator to position the machine in any orientation with minimal effort.

With a 12” depth of throat, this innovative design is the largest portable machine that we have built to date. This machine is a simple 4 tonne press and due to extensive FEA analysis, we were able to manufacture the product to weigh only 138 lbs! Strategically designed to reach into tight spaces, this design also features a rotating gimble allowing the operator to position the machine in any orientation with minimal effort. -

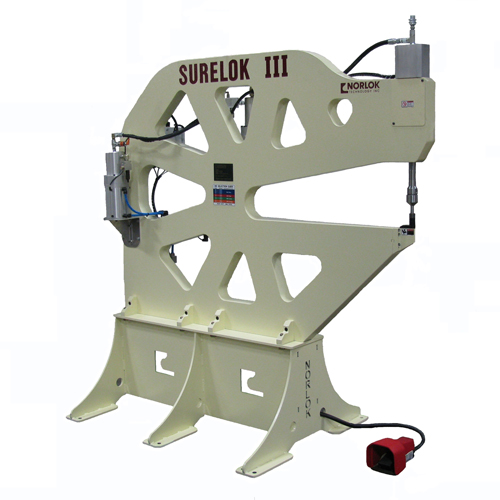

INTRODUCING THE FIRST PNEUMATICALLY POWERED HEAVY DUTY MACHINE Available in 25” throat, the Heavy Duty SURELOK model provides the ultimate strength to ensure all of your heavy material applications are taken care of. Air powered, NO HYDRAULICS, machine can clinch material up to an astounding 10g. FEATURES

INTRODUCING THE FIRST PNEUMATICALLY POWERED HEAVY DUTY MACHINE Available in 25” throat, the Heavy Duty SURELOK model provides the ultimate strength to ensure all of your heavy material applications are taken care of. Air powered, NO HYDRAULICS, machine can clinch material up to an astounding 10g. FEATURES- Available in 25” throat depth

- 2-1/2” stroke

- Typical shear strength for 2-ply 10g mild steel is 1400lbs per clinch

- Fasten materials as thin as 24g and as thick as 10g

- APU – advanced power unit is faster, smoother,

- quieter and uses less air, NO HYDRAULICS

- Single foot pedal operation

- Uses standard shop air supply

- Optional tool kit for fastening stainless steel

- Optional SPR tool kit for fastening aluminum composite, TPO

- Small footprint

-

With our Tagger 320 and 320V1 models, you can stitchfold light gauge metal sheets and light profiles with absolute accuracy and ease. The hand-held, portable machine lets you cut out tabs in just one or two punches.

With our Tagger 320 and 320V1 models, you can stitchfold light gauge metal sheets and light profiles with absolute accuracy and ease. The hand-held, portable machine lets you cut out tabs in just one or two punches.FEATURES

- Complete with work-head, tool kit, handle, hose and booster

- Ready to connect to a source of dry and clean compressed air at 6 bar, 87 psi

- Option to upgrade from 2m, 6ft to 3m, 10ft hose length

-

Designed to easily fasten channel letters, the LITTLELOK 1200 machine has a 12” throat and can accommodate a 6”return, making short work of all your channel letter fastening projects. Whether it is your main fastening machine or a sibling for an existing LETTERLOK product, the LITTLELOK 1200 has all the features you need to effectively clinch and fasten channel letters.

Designed to easily fasten channel letters, the LITTLELOK 1200 machine has a 12” throat and can accommodate a 6”return, making short work of all your channel letter fastening projects. Whether it is your main fastening machine or a sibling for an existing LETTERLOK product, the LITTLELOK 1200 has all the features you need to effectively clinch and fasten channel letters.FEATURES

- 12” throat

- Accommodates a 6” return

- Operate at 60-80 cycles per minute

- Maximum combined material thickness of 0.125”

- 100% air powered

- Adjustable table

- UL recognized clinch for channel letters

-

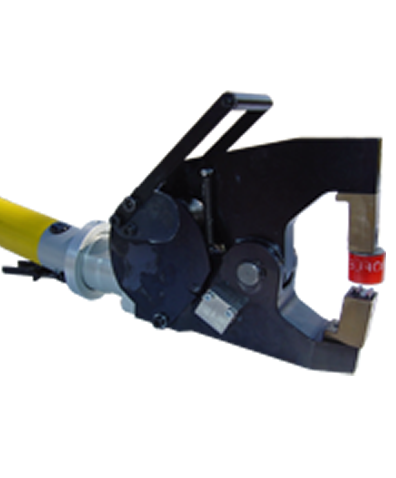

A reliable and portable machine perfect for anyone in the steel studding industry. Choose from three small, light-weight and compact designs that offer versatile ways to effectively single and double-stroke clinch.

The ASTRACLINCH Alligator series has been fundamental in the transformation of the commercial and residential light gauge structural steel building industry.

FEATURES

- Low investment (for lower production costs)

- Rigid punches & robust dies give low tool consumption & minimal operating costs

- Reversible punches & dies

- Manual jaw closing for maximum safety

- No separate fasteners to buy, sort or feed

- No thermal stress around the joined area

- Highly consistent joint

- Rapid, non-destructive testing of the joint

- Low machine weight

- Joining more than two layers

- Pre-painted or galvanized sheet materials

Shopdtadmin2024-02-14T20:40:49+00:00