Surelok II – E & P Series

Surelok II – E & P Series

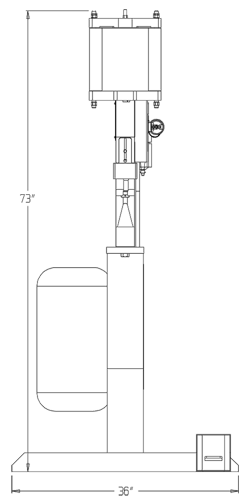

Our standard floor mounted machines are guaranteed to outperform the competition. The SURELOK II E series machine is our basic entry level machine that offers proven clinching technology.

Our SURELOK II P series is our production oriented machine. Successor of our SURELOK II E series machine, the P series offers greater clinching versatility and is able to fasten material from as thick as 14 gauge to as thin as 32 gauge. Proven clinching technology you can count on.

The SURELOK II E and P Series’ operating features and versatile designs offer solid and reliable machines that become your go-to clinching solutions.

FEATURES

- Rigid steel frame offers less deflection for longer tool life

- Close tooling access to get in close for more applications

- Fast cycle times for increased production

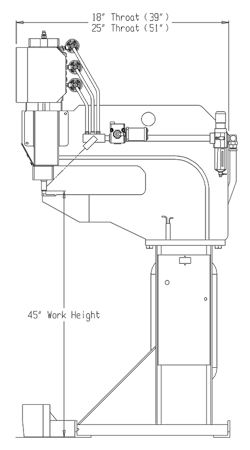

- 18” or 25” throats for greater reach for larger parts

- “Intelligent” safety stroke for greater operator safety

- Direct acting power stroke for more reliable joints

- Simple tool adjustments for little or no setup time

- Adjustable stroke that reduces pinch point and air consumption

- Upgradeable feature allows you add what you need, when you need it

- 25 years of design experience with proven reliability and quality

- Air powered (requires no electrical hookup)

- Affordable prices for low investment and faster payback

Download Brochures:

Standard Features: |

|||

| Throat 18″ or 25″ | Choose the depth of frame behind punch | ||

| Urethane punch assembly | Reliable tooling with urethane stripper | ||

| Close reach lower arm | Clinch in tight areas – also great for pipes | ||

| 2 piece die holder and insert | Fast to change and easy to clean | ||

| Adjustable stroke | Adjust open height to minimize pinch point | ||

| “Intelligent” Safety stroke | Reduces pinch point to less than 1/4″ even with 1″ stroke | ||

| Lexan guard | Eye protection without restricting access | ||

| Air surge tank | Minimizes the effects of poor air supply | ||

| Air filter / regulator | Nothing to add – just plug your air line into the tank | ||

| Frame mounted tool kit | All tools required for adjustments are included | ||

OPTIONS |

“E” |

“P” |

• Included X Optional |

| Production punch assembly |

X

|

•

|

Our best tooling with longest punch and die life, best part access, best material range, and easily modified. |

| Auto return |

•

|

• | Automatic (timed) press return – adjustable to suit application and air pressure. |

| Advanced power unit |

•

|

•

|

A fast, production oriented power unit – increases press speed by approximately 10%. |

| Extended Warranty |

X

|

•

|

Extends standard warranty to 3 years (punches and dies excluded). |

| High speed control |

X

|

•

|

1 touch operation with increased speed & reliability – includes pressure sensing circuit. |

| Laser pointer |

X

|

•

|

Shows where clinch will be made – easy to use – meets all regulations for laser pointers. |

| Side table |

X

|

X

|

12″ x 18″ swivel table – great for holding small parts and tools. |