-

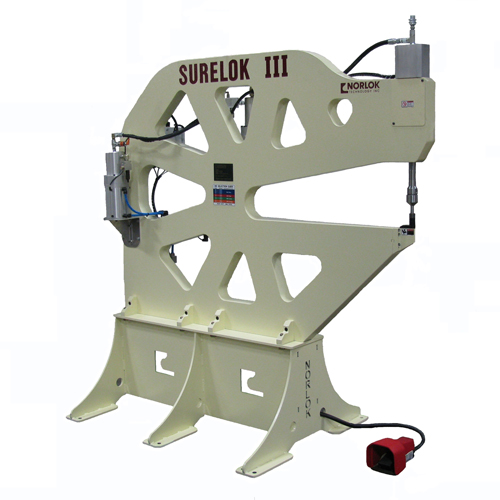

A 10 tonne press custom designed with larger depth of C frame, capable of clinching up to 10 gauge material. This particular press featured a “dead man” switch foot pedal and integrated QC control safety monitoring. In addition to the full complement of round and rectangular tooling, its design allowed for hole punching and self piercing rivet capabilities.

A 10 tonne press custom designed with larger depth of C frame, capable of clinching up to 10 gauge material. This particular press featured a “dead man” switch foot pedal and integrated QC control safety monitoring. In addition to the full complement of round and rectangular tooling, its design allowed for hole punching and self piercing rivet capabilities. -

With a 12” depth of throat, this innovative design is the largest portable machine that we have built to date. This machine is a simple 4 tonne press and due to extensive FEA analysis, we were able to manufacture the product to weigh only 138 lbs! Strategically designed to reach into tight spaces, this design also features a rotating gimble allowing the operator to position the machine in any orientation with minimal effort.

With a 12” depth of throat, this innovative design is the largest portable machine that we have built to date. This machine is a simple 4 tonne press and due to extensive FEA analysis, we were able to manufacture the product to weigh only 138 lbs! Strategically designed to reach into tight spaces, this design also features a rotating gimble allowing the operator to position the machine in any orientation with minimal effort. -

An automated floor-mounted machine capable of 3500mm x 2350mm platforms, this custom machine automatically sizes for an infinite variety of platforms with a stored library and bar code scanner. This particular machine has been a critical piece of equipment in crucial plant-line running parts since 2012.

An automated floor-mounted machine capable of 3500mm x 2350mm platforms, this custom machine automatically sizes for an infinite variety of platforms with a stored library and bar code scanner. This particular machine has been a critical piece of equipment in crucial plant-line running parts since 2012.FEATURES:

- A dual 10 tonne work head

- 5 foot depth of C frame

- Automated QC analysis software indicating clinch quality

- Full colour touch screen HMI (Human Machine Interface)

- Large entry and exit tables for part movement

- Full hydraulic and pneumatic automation