Power Line

Power Line

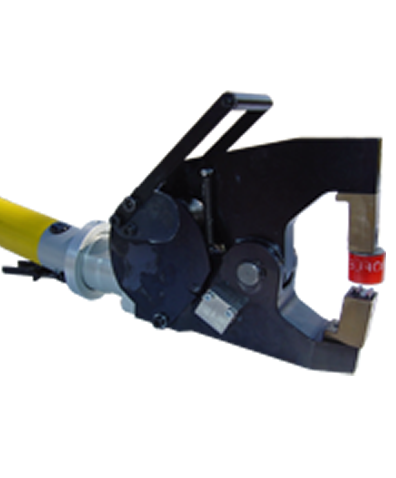

In two-stroke clinching, the material to be joined is first deformed plastically inside a die. In a second phase, the joint is created through a squeezing between the punch and anvil outside of the die. The result is a high quality joint in terms of shape, strength and repeatability.

WHATS INCLUDED

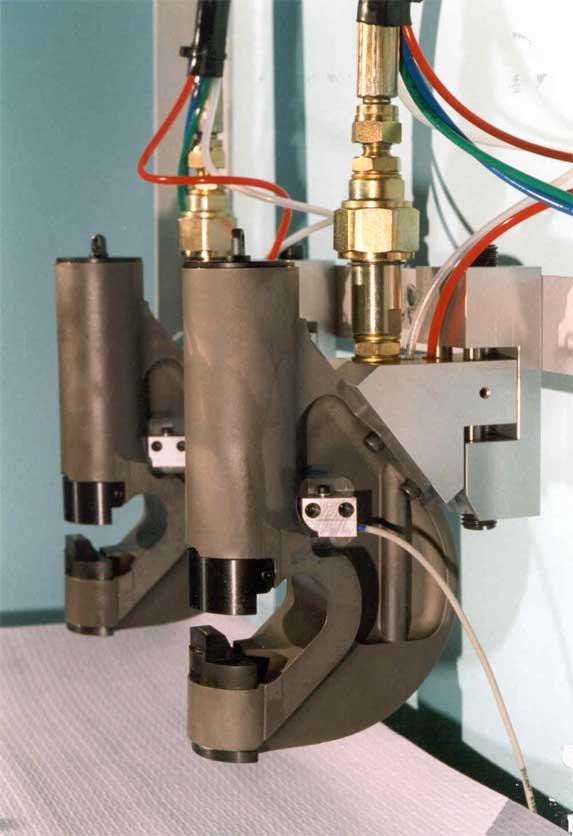

A complete ASTRACLINCH Power Line unit consists of a compact workhead connected through a hydraulic hose to an air-over-oil pressure intensifier (booster) with automatic cycle control, ready for connection to the

factory compressed air net. An air preparation unit with pressure regulator, filter and water trap, a variety of tool kits, balancer and rotator are available as options.

FEATURES

- Clinch up to 2 layers of 16 Gauge Mild Steel (.160″ or 4mm total thickness)

- All Pneumatic Operation, uses standard 90psi (6bar) shop air.

- 2 stroke clinching operation.

- Stainless Steel Ready (up to .120″ (3mm) total material thickness).

- Very Close Edge Access. Center of clinch within 1/4″ (6.3mm) of flange edge.

Download Brochures:

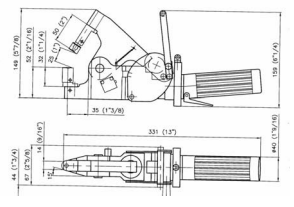

Technical Data

| Workhead weight | 7.5 lbs | 3.4 kg |

| Working air pressure | 87 psi | 6 bar |

| Hydraulic pressure at 6 bar | 5,260 psi | 365 bar |

| Cycle time | 1.2-1.9 s | 1.2-1.9 s |

| Max thickness, mild steel | 0.160” | 4 mm |

| Max thickness, stainless | 0.120” | 3 mm |